Details of the Project

The engine that powers the generator set is an industrial, heavy-duty diesel engine, it has specifically designed and optimized to power generator sets. The engines vary from 2-strpoke to 4-stroke compression ignition types. Full details of the engine and associated equipment is provided in the engine manual of the OEM. If regular preventative maintenance is performed as per the OEM’s engine manual, the DG will continue to provide reliable power for many years.

Corrosion in the radiator could be a prime cause of failure. This is prompted by air in the coolant. Always ensure pipe connections are free of leaks and bleed air from top of the radiator regularly to keep the system “air free”. Radiators should not be left in a partially filled condition. Radiators left partially filled with coolant will suffer much more rapidly from effects of corrosion.

Project Pictures

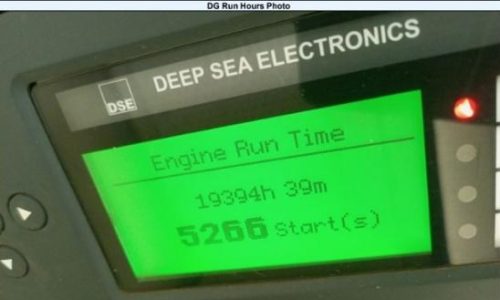

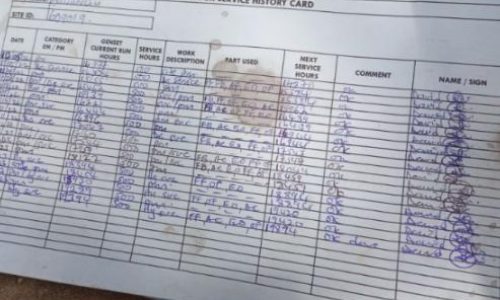

Engine Maintenance

The engine that powers the generator set is an industrial, heavy-duty diesel engine, it has specifically designed and optimized to power generator sets. The engines vary from 2-strpoke to 4-stroke compression ignition types. Full details of the engine and associated equipment is provided in the engine manual of the OEM. If regular preventative maintenance is performed as per the OEM’s engine manual, the DG will continue to provide reliable power for many years.

Radiator Maintenance

Corrosion in the radiator could be a prime cause of failure. This is prompted by air in the coolant. Always ensure pipe connections are free of leaks and bleed air from top of the radiator regularly to keep the system “air free”. Radiators should not be left in a partially filled condition. Radiators left partially filled with coolant will suffer much more rapidly from effects of corrosion.